With the continuous development of the automobile industry, the role of alloy wheel lathes in the field of wheel repair has become more and more prominent. Utilizing advanced technology and high-precision operation, this equipment not only repairs the appearance of the wheel, but also positively affects the performance of the wheel, thereby extending its service life. Here are a few key factors that influence wheel performance with alloy wheel lathes:

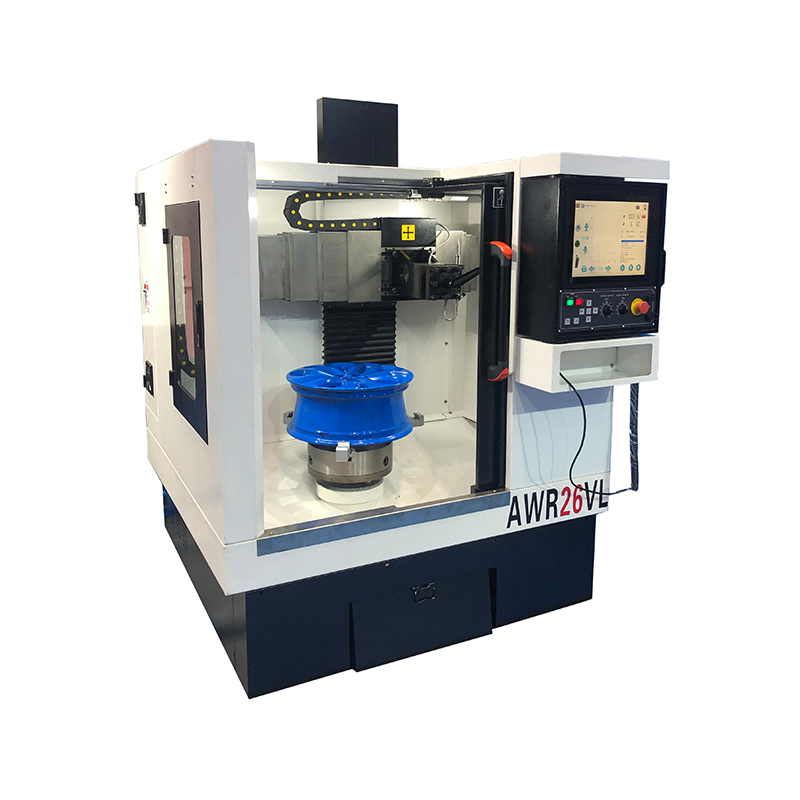

Surface roughness: The roughness of the wheel surface has an important impact on its guidance, braking performance and handling. Through the precise operation of an alloy wheel lathe, wear and scratches on the wheel surface can be eliminated, restoring a smooth and consistent surface quality. This treatment can make the contact between the wheels and the ground more even, improving the vehicle's stability and braking effect.

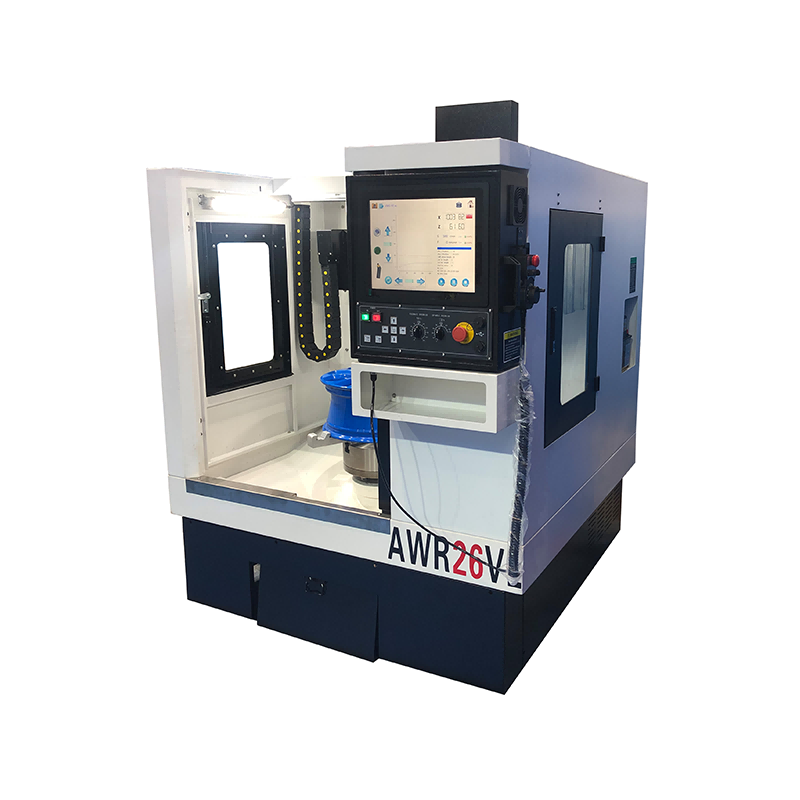

Wheel Hub Structure: Alloy wheel lathes are able to repair and adjust the wheel hub structure to ensure it meets design requirements. This includes wheel diameter, rim angle, and the mounting plane of the tire. By accurately adjusting these parameters, the assembly accuracy of the wheel can be improved and abnormal vibration and tire wear of the vehicle during driving can be reduced.

Mechanical properties: Alloy wheel lathes can detect and repair the mechanical properties of wheels, such as the strength and stiffness of the spokes. Once problems arise, such as embrittlement or deformation, the wheel may be subjected to greater loads, leading to earlier fatigue failure. Prompt repair of these problems through an alloy wheel lathe can ensure that the wheels will not suffer serious failure during long-term use.

Balance: Alloy wheel lathes are able to accurately detect and correct wheel imbalances. Wheel imbalances can cause vibrations and shakes in the vehicle, increase driver discomfort, and place greater loads on other wheels and suspension systems. By using an alloy wheel lathe for balance correction, the stability and comfort of the wheels at high speeds can be ensured.

Overall, alloy wheel lathes play a key role in wheel restoration, not only fixing cosmetic issues with the wheels but also having a positive impact on the performance of the wheels. It can extend the service life of wheels, improve driving comfort and ensure driving safety by improving surface roughness, adjusting wheel hub structure, repairing mechanical properties and correcting balance. The alloy wheel lathe has become an indispensable tool for the car repair industry and car owners.